Summary of maintenance manual for settlers with lamellar modules

posted in News by TecnoConverting

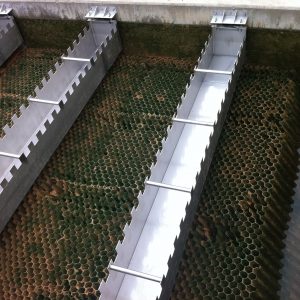

The lamellar modules, generally made in PVC or PP, are very fragile profiles to accelerate the particles sedimentation on WWTP and DWTP settlers. With the correct study and a good sizing of the lamellar system it´s possible to multiply per four the performance of the settler.

In order to maintain the performance achieved with the proper sizing of the lamellar system, it´s important to follow an effective maintenance routine at least once a year.

Some typical problems that occur in lamellar settlers is that there is not a correct maintenance are:

– Clogging of the lamellas

– Deformation of the modules

– Breakage of the lamellar profiles

– The support structure falls due to lamellas clogging

The following steps explain how to make a good maintenance of the lamellar system:

1. With the settler totally filled with water, start to throw water at high pressure in all lamella surface. As water cleans all lamellar surface the operator should slowly lower the water level in the settler. It´s important to dilute all the organic matter adhering to the lamella walls, preventing it from drying out and also from reducing the settling capacity.

2. While the lamellas are being clean at surface the operator should slowly empty the settler. The scraper system or the sludge extractor must be operating in order to remove all the organic matter that is coming out from cleaning.

3. With the settler already empty, the operator shall perform an internal inspection of the equipments. It is possible to remove one of the lamellar modules to allow the operator to check the bottom of the settler and facilitate the inspection tasks.

It´s important not to forget to verify:

– In case the support structure is in carbon steel, check if it is not rusted or with any degradation.

– That the lamellar modules are correctly supported by the under structure

– There´s no remaining clogged lamellar parts.

– If there is clogged parts of the lamellas by sludge, ensure that there´s no generation of preferential channels that can decrease the lamellar efficiency.

– The sludge scraper state, if there is any wear on the wheels and on the concrete.

4. Cleaning of troughs channels for treated water collection.

5. Slowly fill the settler with water and verify that the lamellas have an anti-floating to prevent them from moving from they´re place and come of the under structure due to the hydraulic pressure from the water filling.

Before proceeding with the inspection of the equipments it´s important to ensure that the lamellar under structure is in good condition and has not fall of due to the sludge weight. Not always the support structure is dimensioned considering the possible lamella clogging: if 1 m3 lamellas weights 50 Kgs approximately, the same lamellar module with 100% contain of sludge can weight 1300 Kgs.

It is not recommended to leave the settler empty for long time, since the continuous exposure to the sun can weaken the status of the lamella.