Detail Engineering sets the difference in the Water Sector

posted in News by TecnoConverting

TecnoConverting Engineering was born in 2005 as a specialized company for the manufacture of water treatment equipment focused in providing solutions to the diverse problems that were present in the Water Treatment Sector. The bet for technology and the initiative to develop its own R&D, has made possible a continuous growth and a specialization in settling processes and lamella modules.

Its philosophy, which is work hard daily and provide the best possible service and the best solutions to its clients, made it possible for them to become the only Spanish company specialized in lamellar settling, a great achievement in a Sector where adaptation to the new needs is the key to differentiation. TecnoConverting counts with its own team of technicians to perform the complete installation, therefore securing maximum quality in the installation and the possibility to adapt the best solution based on the particular need of each one of its clients.

TecnoConverting is the leading Company in lamellar settling knowledge and the highest reputation in technology for the Water Treatment Sector internationally

The company’s’ base strategy is continuous innovation, which has allowed them to position itself as the company with the most knowledge in lamella settling and most technologically advanced reputation in the water treatment sector internationally; advising engineering firms, construction corporations and public organisms around the globe. From its headquarters in Sant Fruitós de Bages (Barcelona) with more than 2.400 m², TecnoConverting engineers, designs tailor made and made to measure, fabricates and installs the technically best solution in settling

TecnoConverting engineering as Added Value

TecnoConverting Engineering is one of the major engineering firms in our Country and one of the very few specialized in lamellar settling globally. Besides developing new installation projects, retrofit and drinking water plants, it also performs extensions and improvements in water treatment as well as acting as an integrator of the best technologies for a better performance of the plants.

TecnoConverting Engineering possess 3.500 m² destined to engineering and equipment fabrication.

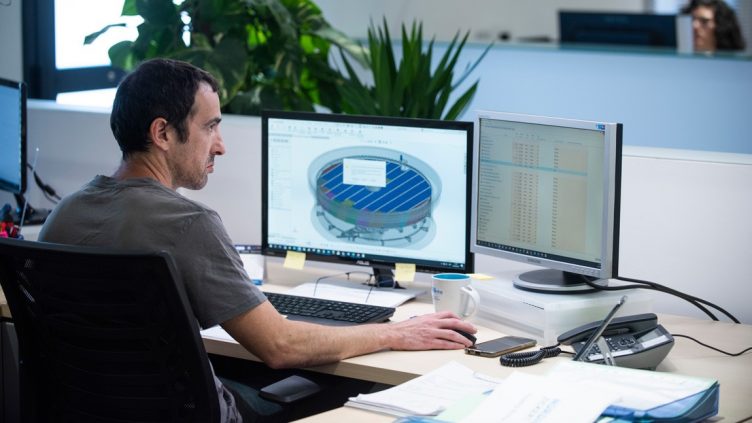

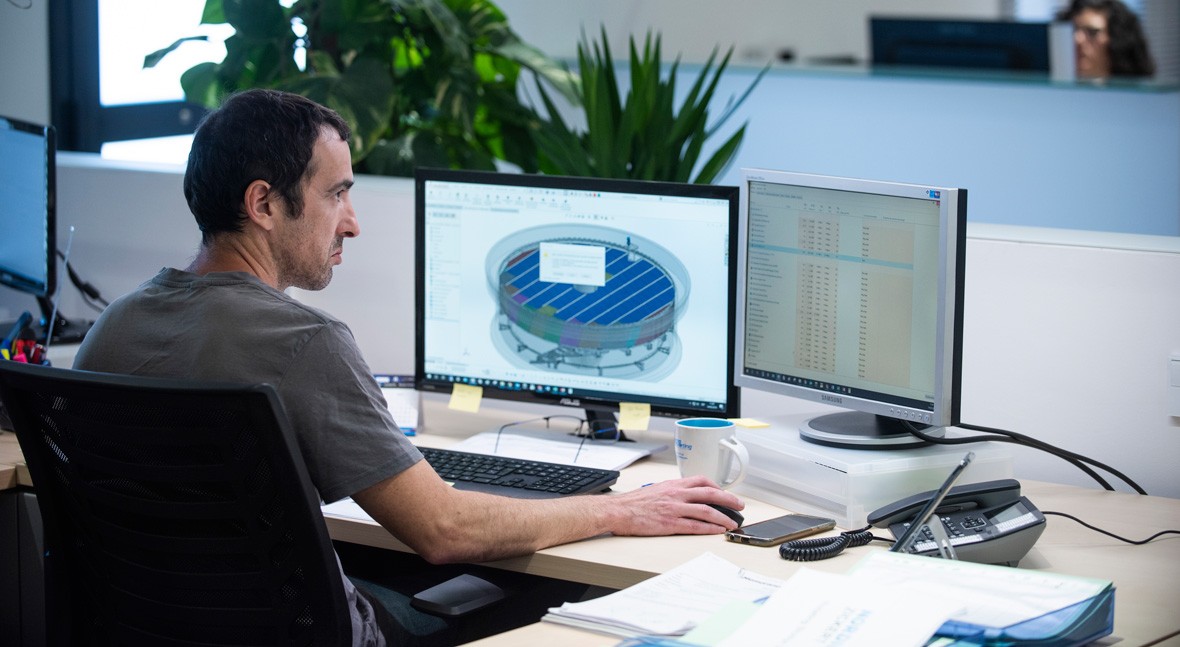

They receive a very high volume of enquiries, which are meticulously studied by the team; a customer service at the very top. This is how the company develops for its clients engineering work destined to a better process and equipment design for the water treatment. And it´s the case, once an enquiry is received from a client, a commercial department comprised of engineers studies the feasibility of each case and, based on the data received, determines if the information is sufficient to prepare an offer and send it to the client.

Once the offer has been approved, the engineering department takes over and begins by studying the existing data, performing structure calculations to all projects and performing simulations in CFD (Computing Fluid Dynamics), for which they are pioneers, to secure the highest efficiency of the processes. This level of attention, occasionally, requires new measurements and on site verifications, which makes TecnoConverting’s team to travel even out of Spain to offer the maximum attention possible to their clients.

With all verifications performed, equipment fabrication commences, which is made by the company. TecnoConverting has 3.500 m² destined to engineering and fabrication of all of its equipment, which includes:

- Metal workshop where the Manowar®, Tecno-Classic scrapers, Thompson Launders, skimmers and so on are fabricated.

- Assembly line for the lamella modules, the most advanced one in the market, allowing a better module quality and a lesser fabrication time.

- Plasma cutting also used for prototypes that are constantly developed.

- Mechanization workshop, with the latest technology such as numeric control for a higher precision in all parts.

Research & Development department

TecnoConverting Engineering is also, the only company in Spain that does not hire subcontractors for installation or mounting of their equipment, which accelerates the projects development. All of the installations performed by TecnoConverting has been made by its own specialized technicians, which secures the level of quality to all of their clients. Thanks to its <> system, installation is simplified without jeopardizing the equipment quality, therefore it can be performed by the projects personnel, thus reducing overall installation costs.

- In smaller installations, with TecnoConverting’s Easy-Install system, no specialized technicians are required, which allows their clients to use their own personnel.

- In medium and more complex projects, TecnoConverting sends one supervisor to guide the client’s personnel in the system’s installation.

- In those occasions in which the client does not have the skills or the means to perform the installation, TecnoConverting’s team travels to the location and performs the complete installation.

One of TecnoConverting advantages by having its own workshops and team of technicians is that they have a profound knowledge of the equipment and therefore detect a bad measurement, the settling tank form or a diversity of on-site setbacks that cannot be seen in the drawings.

This is how, by the diverse departments (commercial, engineering, purchasing, fabrication, research & development or finance), which form TecnoConverting gears, the company has become in one of the major engineering firms of our Country. Its differentiation as one of the few engineering firms specialized in lamellar settling worldwide, motivates the clients to go to them in search of the most reliable solution to their needs.

TecnoConverting’s engineering crosses borders

Spain is a world power in water treatment. The best engineering firms are located in Span and although sometimes our country is seen as with less technical knowledge, the Spanish companies operate with incredible high levels. TecnoConverting is, without doubts, one proof of this.

Although its operational center is located in its offices in Barcelona (Spain), the company exports to more than 30 countries, with its own offices in Portugal and France and delegations in Rumania and India. In fact, its presence in the international market has been increasing on a yearly basis, achieving 70% of turnover from export.

Besides, the Company exhibits its work in the most important exhibitions of the sector: SIGA in Madrid, Water Management Exhibition in the Czech Republic, Weftec in The USA, Pollutec Lyon in France and Aquatech in China.

This international trend has taken them to develop projects in several Latin-American countries as a contribution in the improvement of the supply and cleaning services in the Dominican Republic, the impulse of the new trend in the industrial sector in Mexico or the improvement of the infrastructure of the Chilean Valparaiso region. All of them have made TecnoConverting in a fundamental ally for the development of the water sector in Latin America.

A fundamental part for the Water Sector development in Latin America

TecnoConverting places itself with strength in Latin America thanks to its success in Chile, Venezuela and Mexico, and it’s just the beginning.

A differentiation character

Around TecnoConverting Engineering technology design, its engineering team has been developing, for some time now, complete process units by integrating other equipment and technologies available in the market. This has made possible that the companies’ brochure offers a wide array of solutions perfectly adapted to the water treatment most frequent and important problems.

Lamella Modules: Modules for the settling process in the water treatment

TecnoConverting’s lamella modules have been designed to provide more efficiency in settling, being one of the lamellas that increase most the projected surface. Besides, from the moment the dimensioning calculations are made by the team, the fabrication is made to measure, with the most convenient material, in short, the best lamella for each settling process. They are suitable for purification, drinking water and storm tanks.

Manowar bridgeless diametric scraper: Scraper for water treatment

The Manowar scraper is an innovative and improved system if compared to the circular bridge scraper. Maintaining the same function, with it all defects of the old systems are corrected at once. With the traction unit anchoraged to one extreme of the settling tank, the client will no longer view a girating bridge but two flights that level themselves with the water level.

Depending on the projects needs, TecnoConverting manufactures the circular scraper Tecno Classic (for settlers and thickeners) and the rectangular scraper (water and wastewater plastic technology).

Thomson Collection Trough

In GRP, PVC, polypropylene or Stainless Steel, TecnoConverting designs and fabricate the Thomson collection trough for any type of application. Engineering calculations that support a better performance, calculating the V-notch optimum size and height.

Tubular Skimmers: for the floating scum removal

Based on the treatment flow, TecnoConverting calculates and designs the best tubular skimmer for the floating scum removal, allowing with it an all-time clean settling unit.