TecnoConverting CFD simulation

posted in News by TecnoConverting

The future of water treatment

Imagine that before building a waste water treatment plant or drinking water plant you know if it will work correctly, if it will be well dimensioned or that it will be the most efficient possible. At the same time, you have the ability to evaluate alternatives in record time and at a very competitive price. What can you achieve with this? Ensure the highest quality of the treated water and save money, money in civil engineering, in oversized equipments or even in space. For the Spanish market probably is not much output, relatively small plants, there are few new works and what is coming in the near future are remodeling or upgrades of existing plants, but in a global market, with emerging countries that need to treat more water increasingly, and where plants are giant, simulation stands as the future in water treatment.

When TecnoConverting started with the CFD simulation, our idea was to focus on the biological and settling processes, especially lamellar settling, since we found that preferential channels are created but we didn´t know exactly why. We also found that there were some areas with more sludge accumulated than others. From these findings we began to assume that if preferential channels or areas with of greatest sludge accumulation existed, meant that the lamellar does not work uniformly, meaning that, there were areas working more and areas working less.

From these questions and concerns, we presented our project to INNPACTO funded by the ministry, after informing the corresponding assessment, the administration approved the project noting has a considerable technical improvement our simulation project.

1. CFD simulation in lamellar modules

TecnoConverting Engineering uses dimensional multiphase analysis using computational fluid dynamics (CFD) for the complete study of a settling system in order to determine its hydraulic performance and suspended solids of lamellar settlers.

2. CFD simulation fundamentals

The CFD technique involves solving a set of mathematical equations and nonlinear partial derivatives which govern the behavior of one or more fluids. These equations, called Navier – Stokes equations are the conservation of mass, conservation of momentum and energy equation.

The most common method of solving these equations is the method of finite volumes. Using this technique, the region of interest is divided into small regions, called control volumes. The equations are solved iteratively and for each control volume while maintaining the overall balance of the main variables of the studio system. As a result, the value of each variable (pressure, speed, temperature, Reynolds, vorticity, etc.) throughout domain is obtained, thus determining the overall flow behavior.

3. CFD simulation results

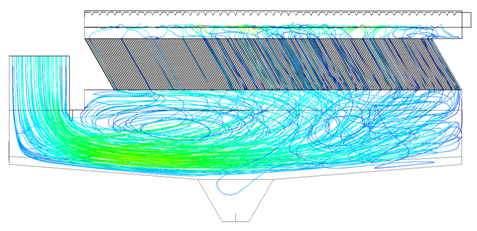

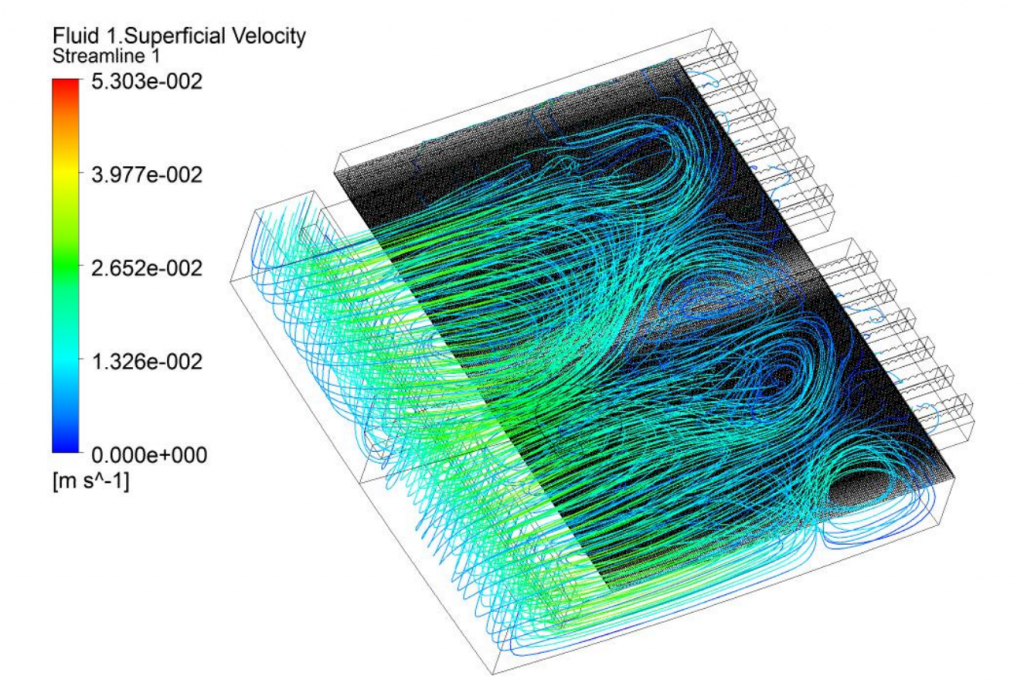

Through CFD calculation for lamellar settler we obtain the distribution velocity of the water throughout the tank in study, the possible presence and location of turbulence and recirculation zones, and the determination of preferential flow paths of water with lamellar system. Also, by adding a representative set of suspended solids, these paths are evaluated analyzing its speed through the lamellar system, and we can determine the overall efficiency of the settler.

Results of a model example (water flow lines, lateral view cut)

The figure shows the flow lines of the water through the lamellar. With these results we can see how the process will behave, even in different operating configurations or different types of solids, representing the operation of the equipment at average and peak flow, and with different seasons water. In addition, you can incorporate baffles and geometric changes, assessing the behavior of the system in each case in order to find the best possible performance at a time and cost infinitely less than by experimental evidence.

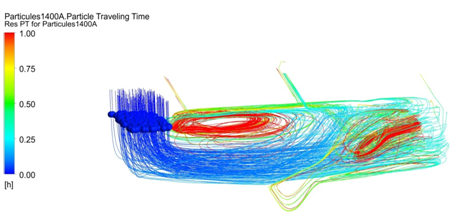

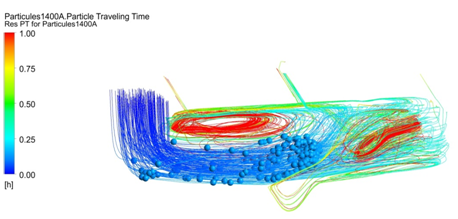

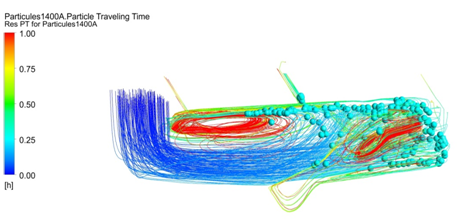

On the following images we show the trajectories results of suspended solids through the studied settler. In a very visual way it´s possible to observe at different time instants where the solids pass and areas of stagnation or recirculation of these, and where there may be undesirable escape of solids.

Results of a model example (Path of the particles, instant 1)

Results of a model example (Path of the particles, instant 2)

Results of a model example (Path of the particles, instant 3)

4. Interpretation of obtained data through the simulator

From the obtained data through TecnoConverting Engineering CFD calculation, we can design settlers to the actual needs, for example:

Smaller sizes and more efficient settlers, optimized geometry. Savings in civil engineering, space and equipments.

- Is sized exactly the necessary lamellar, thus avoiding to pay extra costs to incorporate lamellas of unsuitable sizes or spacing. Significant financial savings.

- The necessary Thomson channels (effluent throughs) are defined so settler works in the most efficient way without creating preferential channels, in quantities and measures adjusted to the needs. Saving materials and civil works.

- Ensures a minor clogging of the lamellar, which means saving in maintenance

5. What has discovered TecnoConverting that can help you improve your lamellar settling?

- As Thomson channels negatively affect the lamellar scraper and if they are not located properly creating preferential channels.

- What type of effluent troughs channel best for your installation, Thomson type, tubular, GRP or stainless steel?

- How do you have to place the lamellas in the settler to increase efficiency, they must be assembled upstream or in the direction of the flow?

- Where to place the water inlet in a lamellar settler in order to be the most efficient possible.

- What lamellar type must be used in each case. For example, in potable water treatment companies normally use small spacing, but why? Is it really necessary to pay more for little spacings?

- If exists corrected Hazen speed or corrected lift speed rate, how does it affect my lamellar settler?

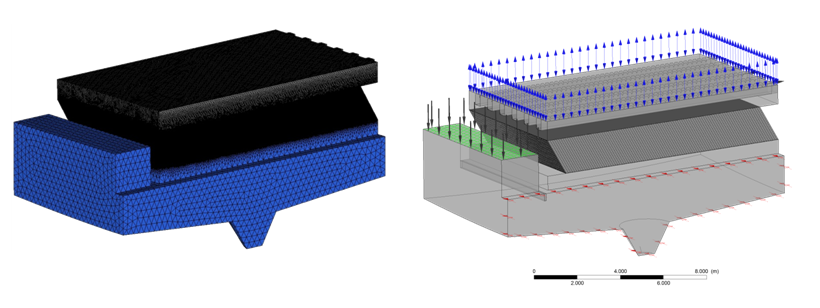

3D meshing and distribution of variables in the lamellar settler